Triplex Fuel Oil Pump Sets

These fully integrated, engineered, self-contained, pre-packaged and pre-wired package pumping systems are the perfect answer to meet today’s high performance and reliability standards found in commercial, industrial and institutional applications. With a wide range of flow rates, our pumping systems provide a reliable means for the transfer of fuel to oil burners, day tanks or emergency generators where system head pressures range from 0 to 200 PSI.

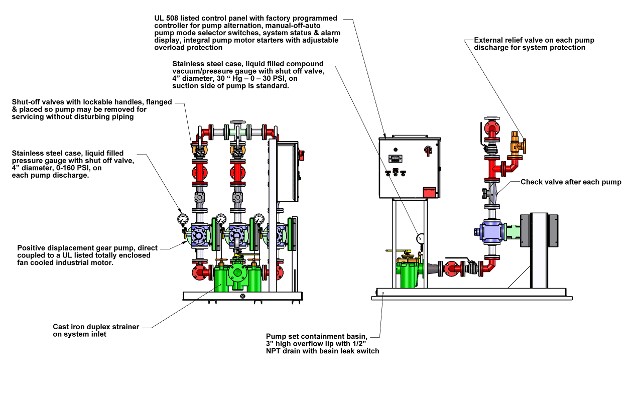

Suitable for pad mounting, our pump sets are factory-assembled on a heavy duty structural steel containment basin with all pipes and fittings welded and flanged. At the heart of each system is a rugged, cast iron, positive displacement pump designed for long life and continuous duty.

Each pump is selected for system specific requirements, pressure and flow rates, and is mounted directly to a UL listed single or three phase, totally enclosed fan cooled motor providing direct alignment of the pump and motor. Our involuted “gear within a gear” design reduces gear wear while providing a pump with minimal noise and excellent suction characteristics.

Each system includes:

- Schedule 40, ASTM Grade A-53 black steel pipe with A-105 forged steel socket welded fittings and A-105 150# forged steel flanges.

- Pump set containment basin, 3" high overflow lip with 1/2" NPT drain.

- Duplex strainer on system inlet which allows strainer baskets to be clean without flow interuption.

- Stainless steel case, liquid filled compound vacuum pressure gauge with shut off valve, 4” diameter, 30 “ Hg – 0 – 30 PSI, on suction side of pumps is standard. Additional gauges, other ranges or larger dials are available.

- Three Phillips GP series positive displacement gear pump, 0 – 200 PSI pressure range, direct coupled to a UL listed totally enclosed fan cooled industrial motor.

- External relief valve on each pump's discharge for system protection

- Bubble tight check valves on each pump's suction and discharge to hold prime and for system protection

- Stainless steel case, liquid filled pressure gauge with shut off valve, 4” diameter, 0-160 PSI, on each pump discharge. Additional gauges, different settings or larger dials are available.

- Shut-off valves with lockable handles, flanged & placed so a pump may be removed for servicing without disturbing piping or the operation of the other pumps

- UL 508 listed control panel, system mounted with automatic pump alternation, factory programmed pump controller, manual-off-auto pump mode selector switches, system status and alarm display, integral pump motor starters with adjustable overload protection

Systems are available in single or three phase, 50 or 60 Hertz. Flow rates listed below are based on 1725 RPM, 60 Hertz motors 50 SSU. Please consult us for other types of fuels or other pressure ratings.

Here are our most popular options that get added to a Single Pump System:

Option 1015 - Daytank Hand Pump, piston type rated 20 gallons per 100 strokes

Option 1062 - Duplex strainer in lieu of single basket strainer

Option 1101 - Additional 4" Compound Vac-Pressure Gauge with isolation ball valve on strainer inlet

Option 1258 - Pump discharge flow switch with flow loss alarm indication and automatic lag pump start

Option 1264 - Differential Pressure Gauge with tri-colored scale, magnetic reed switch and clean strainer warning display

Option 1354 - Optional pump set weather proof enclosure with pad mounting feet

Option 1490 - Explosion proof motor in lieu of standard TEFC, single phase

Option 1494 - Explosion proof motor in lieu of standard TEFC, three phase